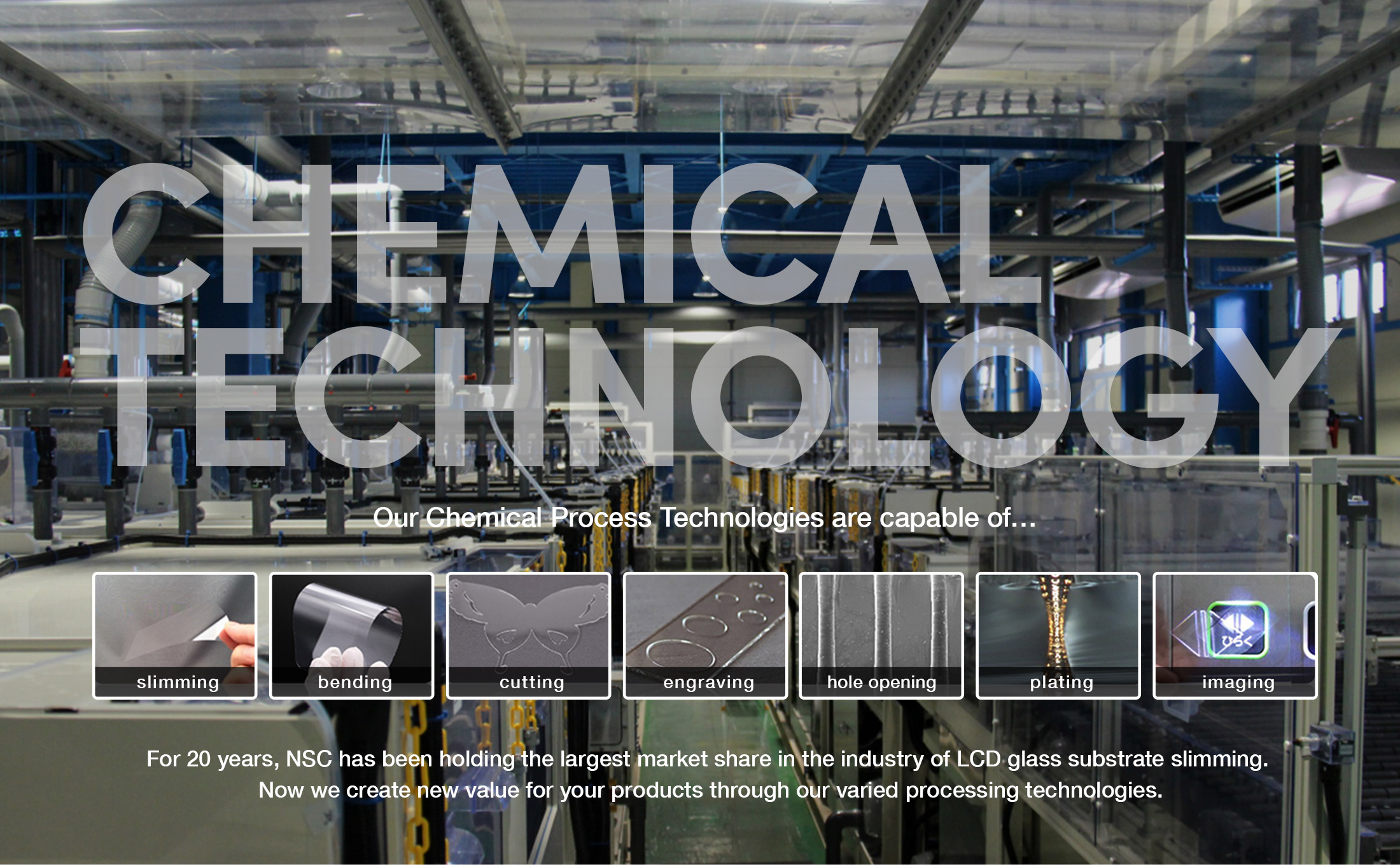

NSC in Future

NSC is engaging in new business fields by utilizing its technologies developed with chemical processes on LCD glass substrates.

Through Glass Via(TGV)

NSC’s TGV fabrication process is capable of fabricating high aspect ratio via on large-sized substrates!

Environmental Business

NSC welcomes inquiries from those business partners who are searching for a method to treat industrial wastes.

Graphene Oxide(Go)

Next generation nano material, “Graphene Oxide” is now ready for mass production!

High-Purification process for Graphite

NSC’s high-purification process for carbon materials and natural graphite can reach the purity of 99.95wt% or higher!

GLASS-RELATED BUSINESSGlass-related business

Equipment Business

NSC provides the whole services from machine design, machine fabrication, to machine installation.

For automatic machines involved with strong-acid or strong-alkali, leave it to NSC!

We design and fabricate machines excellent in corrosion resistance.

↑Click here for the equipment lineup

↑Click here for the equipment lineup